- offers a safe and clear setting for compounding of dangerous drug preparations in compliance with USP and requirements. It really is ideal for operate involving dangerous supplies, antineoplastic, or cytotoxic compounding applications.

These procedures make certain that the isolator don't just meets style and design specifications but in addition performs consistently beneath precise operating situations.

By finishing and publishing this form, you expressly consent for the processing of private data that you simply supply to the needs and in the limits indicated by this conversation, pursuant to and in accordance with art. thirteen of the of Legislative Decree no. 196/03 (Italian Privateness Act).

About the one particular hand, hence, we can easily well say the sterility test isolator nowadays represents a technological common to the business, even though on the other hand, choosing the process which most closely fits your preferences can be demonstrated to generally be not that easy. There are lots of variables to acquire into account: in the most fitted configuration for the development of the procedure which can be to become carried out, to the transfer programs, The mixing from the get the job done tools, up on the sizing of your chambers which should be ample for the level of tests to be carried out, as well as the Area readily available for the installation.

Irrespective of whether you're a pharmaceutical Skilled, an outstanding control specialist, or simply enthusiastic about the intricacies of sterile producing, this in depth manual will supply worthwhile insights into the whole world of sterility test isolators.

What routine maintenance and calibration routines are proposed to help keep sterility testing isolators operational and compliant? Expand To help keep sterility isolators operational and compliant, saily or per-use Visible checks are critical. It is tailin usually recommended to carry out weekly surface area swabs, transfer port checks, and VHP generator inspections.

In conclusion, the WHO standards for sterility test isolators signify an extensive framework created to be certain the best amounts of solution basic safety and top quality in pharmaceutical and professional medical unit production.

Frequent assessments and refresher programs support be certain that operators preserve their skills and adhere to the very best standards of aseptic practice.

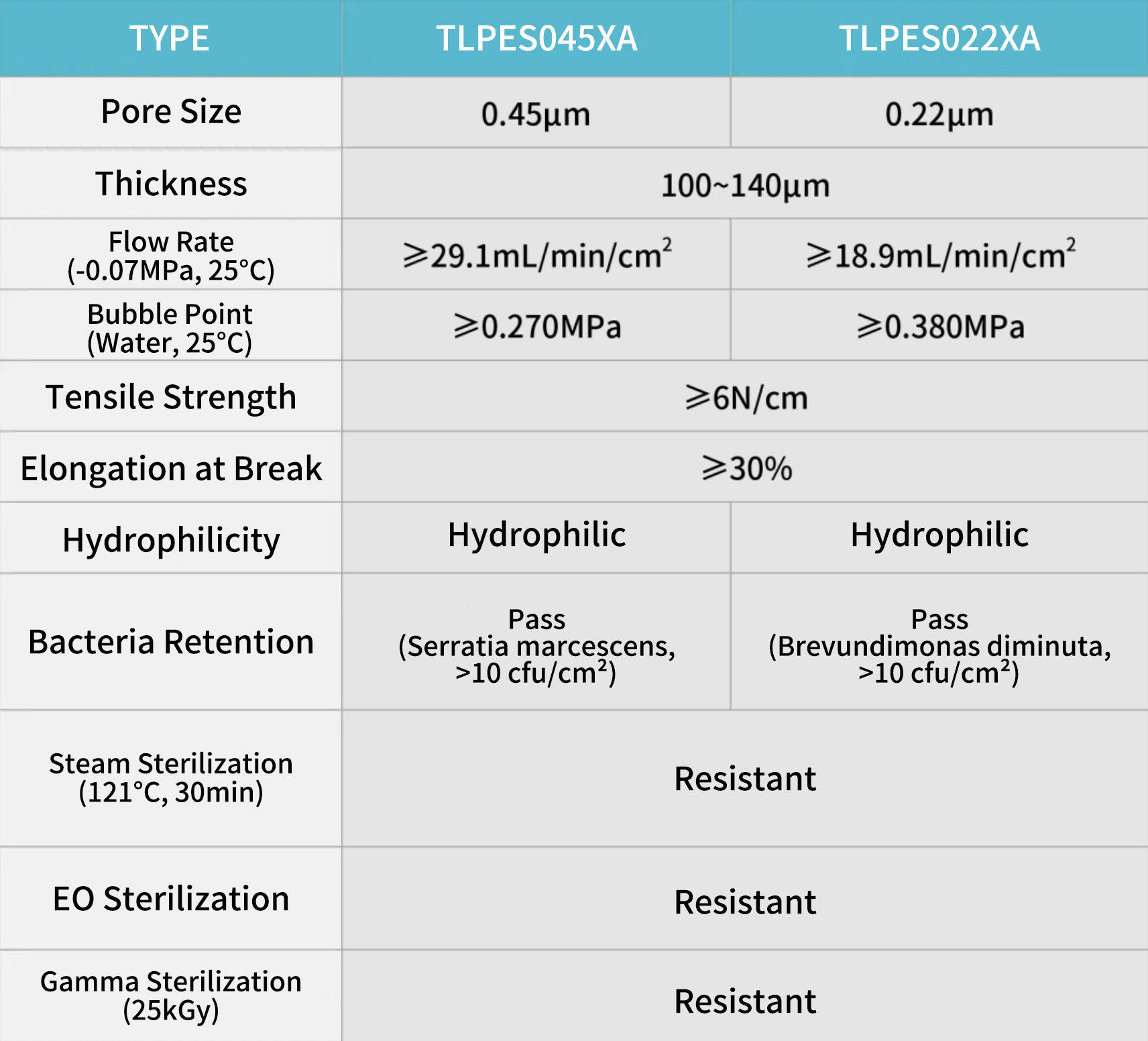

Clear air throughout the do the job zone must be provided by way of a microbial retentive filter (HEPA minimum amount) technique capable of that contains airborne concentrations in the Actual physical sizing and state on the drug being compounded.

ST-IS Collection by Tema Sinergie offers a complete choice of Sterility Isolators, entirely compliant with by far the most stringent cGMP polices and international legal guidelines, precisely created for finishing up sterility tests and quality Management activities in the pharmaceutical area.

Its built-in decontamination procedure guarantees computerized six-log microbial reduction, making certain regular microbiological integrity, though the built-in catalyst provides Risk-free and swift cycle periods. Thanks to its modular and versatile style and design, ISOCARE seamlessly adapts for your approach demands though supplying the ability to specifically match your specific processing desires.

Adverse stress isolator to keep up a decrease inner strain than the external area for sterility testing that entails unsafe compounds.

Qualification of operators generally requires demonstrating proficiency by way of simulated operations and aseptic strategy evaluations.

Absolutely compliant with USP 800 benchmarks, these isolators make sure pharmacies can conduct sterile harmful compounding Together with the utmost self confidence in safety and compliance, thus improving both equally technician welfare and item integrity. Find out the excellence of NuAire's CACI range, the place high quality satisfies slicing-edge technology.